Comprehending the GMP prerequisites as well as their grades is often challenging at times, especially with diverse regulatory bodies in other international locations. What are classified as the dissimilarities among a Grade A, Grade B, Quality C, or Grade D cleanroom natural environment? This article will address:

A cleanroom is any offered contained House exactly where provisions are made to scale back particulate contamination and control other environmental parameters like temperature, humidity and force. The true secret ingredient may be the Superior Efficiency Particulate Air (HEPA) filter that is definitely accustomed to entice particles which might be 0.

Regulators will also be keeping a close eye on developments in The mixture machine–drug product space. Numerous new pharma improvement initiatives and lifecycle administration possibilities are Discovering the integration of health care equipment with drug solutions and buying establishing these systems as a consequence of their therapeutic usefulness and probable price to individuals.

As for differential tension, reduced tension in any with the classified areas should be detected and an alarm need to be elevated for a similar to circumvent the doorway of unclassified air in to the area.

Some functions, like the producing of non-sterile prescription drugs, will not routinely demand a cleanroom, Whilst sterile drugs always do. The GMP clean air grades and classifications define the surroundings in which sterile prescription drugs and biological goods need to be manufactured.

Class allows carriers improve the loading and unloading procedures. By categorizing freight based upon features like dimensions and body weight, carriers can efficiently stack and Manage shipments inside of trailers, maximizing the use of available Room.

30041090Medicaments (excluding goods of heading 3002, 3005 or 3006) consisting of mixed or unmixed products for therapeutic or prophylactic utilizes, set up in calculated doses read more (like Those people in the form of transdermal administration units) or in sorts or packings for retail sale made up of penicillins or derivatives thereof, with a penicillanic acid construction, or streptomycins or their derivatives other

Some cleanrooms are retained at a favourable strain so if any leaks arise, air leaks out on the chamber rather than unfiltered air coming in. This is often most ordinarily the situation in semiconductor manufacturing, where by even moment amounts of particulates leaking in could contaminate The full method, when just about anything leaking out wouldn't be hazardous for the bordering Neighborhood[citation needed].

The benefits of non-oral administration strategies for these intricate and inadequately soluble molecules, in which absorption of the Lively ingredient is simplified and the first pass the metabolism outcome is click here averted, are very well-documented.

Stevanon (CordenPharma): The validation of the parenteral formulation is far more challenging compared to OSD. The quick-performing mother nature of this administration route implies that parenteral formulations are subject matter to stricter compliance rules to make sure affected person safety and should stay in just particular, and usually quite slender, parameters to get acceptance from regulatory bodies.

Cleanrooms as well as their classifications can seem specialized or obscure initially. But at their core, cleanrooms are basically rooms that lower the size and quantity of airborne particles. These particles are the “contaminants” that cleanrooms hold out.

Cleanrooms play a important part in maintaining the integrity and high-quality of products in various industries. The classification method, ranging from Class a hundred to Class one thousand and further than, offers a standardized framework for defining cleanliness specifications and ensuring compliance with marketplace specifications.

three micron and bigger in sizing. All of the air sent to a cleanroom passes via HEPA filters, and sometimes where by stringent cleanliness general performance is critical, Extremely Low Particulate Air (ULPA) filters are utilized.

Lessened downtime: Modular cleanroom installation leads to far fewer disruption to each day operations, allowing quite a few users to maintain some or all operations jogging with no disruption.

Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Monica Lewinsky Then & Now!

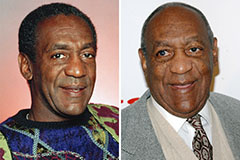

Monica Lewinsky Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!